-

Automobile ignition coil ignites through low voltage change to high pressure, requiring the high insulation grade, working in a very harsh environment, need to meet the requirements of high temperature resistant with waterproof material, and also high requirement of the degassing, metering and mixing; Each casting material which casting into the product with different permeability, it requires very high for the casting volume and casting speed of the equipment , which should meet variable casting requirements.

-

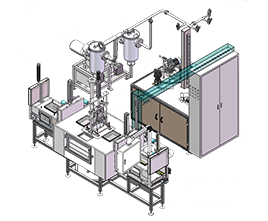

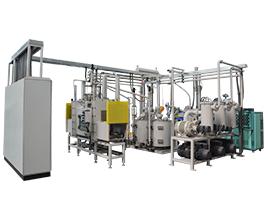

● he epoxy resin adopts the mode of pouring, melting and loading, the material barrel is heated, melted and umbrella thin-film degassed under vacuum in a dumping tank, or a continuous on-line degassing method is used for degassing during loading, then the charging can be used immediately.

● The servo control dosing pump is adopted to ensure the accurate material formulation, mixing through the static mixer. The mixture is even with good effect, fresh material and good flowability.

● The mixture is storage in the second metering cylinder, casting accurately through second metering, setting the casting volume and speed according to the product.

● Degassing, dispensing, impregnation under vacuum

-

●With the mode of pouring, melting, and loading, easy for loading to save working time, continuous on-line degassing has the advantage of high efficiency and rapid degassing

● Servo dosing pump for material formulation, more accurate and stable.

●Vacuum plasma activation cleaning can improve the adhesion of epoxy resin and the quality of products

●Formulation monitor on-line, real time monitoring the ratio accuracy.

● The second dosing distribution, small casting volume and uniform, meet variable casting requirement.

●Triple-chambers vacuum casting with production line to improve production efficiency.

insvac@insvac.com