-

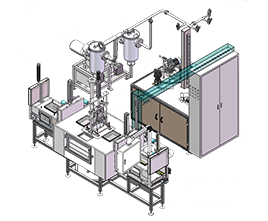

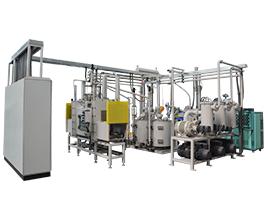

In the power transmission and distribution, the internal coil and other internal components of the CT/PT using epoxy resin as an insulating material, to form a solid insulating material. Epoxy resin and hardener casting into the products by vacuum degassing and formulation metering, then heating to form the solid insulating components.

-

● Small package filler or dust-free ton bag, to prevent dust pollution in the workshop, the filler mixing and heating under vacuum, let the material degassing and dewatering sufficiently.

● Resin, hardener automatically continuous loading, the material will be divided into two non-reactive A/B components, material loading by ratio according to the automatic metering, loading accurate and stable.

● Single-component material mixing and heating under vacuum, adopts the umbrella thin film degassing technology to lift the material through screw to the top, then flow down from the umbrella cover to form a thin film, improving the degassing efficiency.

●A/B component is measured and conveying automatically according to the ratio, uses dynamic or static mixing mode to mix the A/B components, the mixture is delivered into the products mould in the vacuum casting tank. -

●Environmental protection design, energy saving, reduce emission and labor intensity.

●Material automatic loading, metering, mixing, conveying and injection moulding.

●The powerful control system monitors the equipment status and process flow, records real-time the relevant parameters of the production, and the data can be read anytime.

●The application of the double servo robot arm can reduce the size of the casting tank, shorten the vacuumize time and reduce the floor area.

insvac@insvac.com